OEM and ODM Case Studies

Case Study 1

Enhancing Installation with Soft-Closing Features

Project Challenge

To facilitate attachment to mass-produced furniture, the original soft-down lid stay required position adjustments, complicating installation. The primary design challenge was to develop an easily attachable lid stay that retained its soft-down functionality.

Solution

Sugatsune redesigned the lid stay to align with the cabinet's front edge and secure with screws, simplifying installation without the need for specialised skills. Internal springs assist in lifting the flap, while dampers ensure a gentle closing motion. Additionally, the flap holds its position when opened beyond a certain angle until fully opened, providing enhanced user convenience.

Case Study 2

Accommodating Unique Opening Trajectories in Confined Spaces

Project Challenge

The door frame and hinge area contained numerous cables and components, severely limiting space for hinge installation. It was also essential to minimise the gap between the door and frame to prevent foreign debris from entering the compartment.

Solution

Sugatsune developed a hinge that aligns with the cabinet's front edge and secures with screws, allowing for straightforward installation without specialised expertise. Internal springs facilitate easy lifting of the flap, while dampers enable a soft closing motion. The flap also holds its position when opened beyond a certain angle, ensuring stability during use.

Case Study 3

Simplifying Installation of Hinges with Multi-Angle Holding Capability

Project Challenge

Clamshell mobile phones required downsizing and a hinge capable of holding the display at multiple predetermined angles. Previous hinges necessitated adhesives for attachment, complicating production due to curing times. The OEM request included a need to simplify the installation process while maintaining high load capacity.

Solution

Utilising Sugatsune's Motion Design Technology, which includes detent motion, we developed hinges that snap into place and hold at specific angles. We provided the client with various options featuring different torque levels and tactile feedback, allowing for a tailored solution. The hinge not only snaps into place at certain angles but also holds the screen at any angle using a free-stop mechanism, enhancing user convenience. By integrating the hinge into a unit, installation without adhesives became possible. A newly designed ball structure achieved high load capacity, and an interchangeable cap allowed for easy coordination with different phone models by simply changing the cap colour, adding design flexibility.

Case Study 4

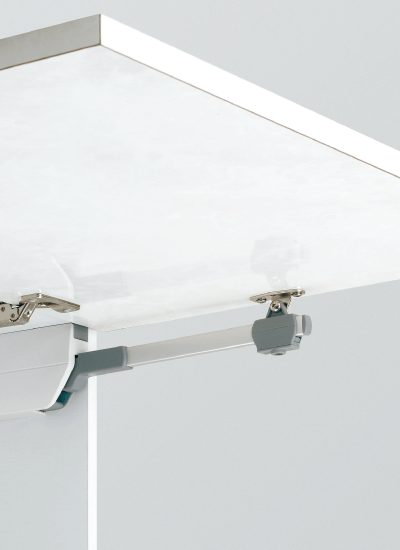

Implementing Soft-Closing Mechanisms in Limited Installation Spaces

Project Challenge

The client desired a top-opening lid that closes softly upon release. However, the installation space was too constrained for standard butt or damper hinges.

Solution

Sugatsune minimised the hinge size by reducing it to its axis, enabling installation in tight spaces. Combining the hinge components into a single unit facilitated easier attachment and detachment, providing additional user benefits.