- Company Top

- About our Products

- Hardware Basics

- torque_hinges

Torque Hinges Hardware Basics

On this page, learn the basics about mechanism and different types of torque hinges and how to choose them.

Use our selection tool for torque hinges to choose the product that meets your needs.

Contents

About Torque Hinges

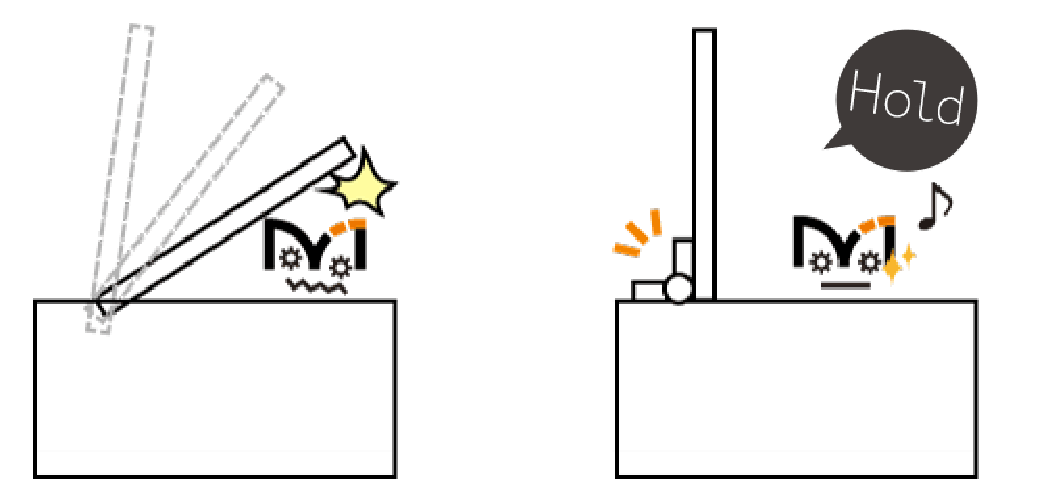

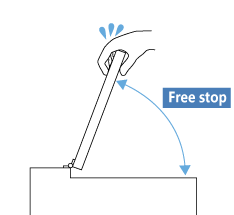

The function is called "Free Stop".

They are widely used to improve usability of products and machinery.

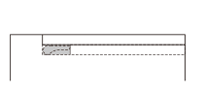

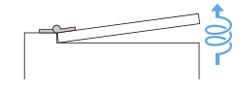

Mechanism of Free Stop

Friction is generated when shifting discs sandwiching a fixed disc are moved.

Friction is generated when a shaft inside a rolled spring sheet is rotated.

Friction is generated when shaft press-fitted into a plastic pipe is rotated.

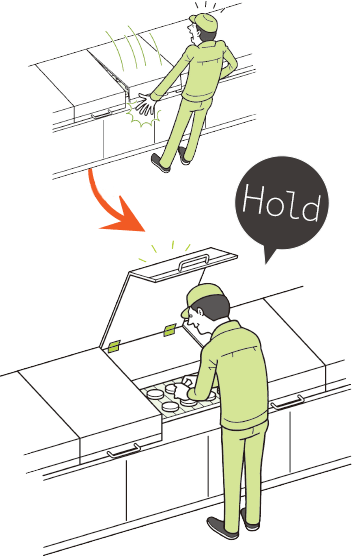

Advantages of Using Torque Hinges

1. Efficiency

2. Clean Design

3. Safety

Torque Hinge by Types

Lift-Off Type/Butt Type

These are common designs for swinging doors.

Bracket Type

This simple design permits various mounting positions for upward-opening lids.

Insert Type

These hinges can be installed by pressing them into place and are invisible from the outside.

Swivel, Dual Axis Type

These hinges often permit a wider range of movement.

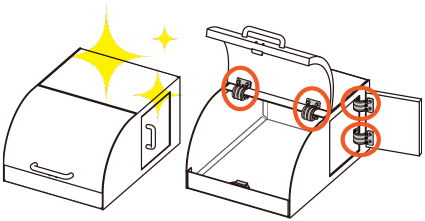

Concealed Type

Same as the standard type, these hinges have a concealed design that is less obtrusive, which contributes to a tidier look.

Concealed Type

Beyond Just Friction

Specialized features provide added convenience and value. Here’s how hinges work using different design features:

One Way Torque Hinge

No torque working in the lifting direction.

Torque also working in the lifting direction.

Friction is applied in only one direction, allowing doors or lids to be opened more easily while still maintaining the position control or “free-stop” once the door is released and friction is applied by gravity in the closing direction.

See productsAdjustable Torque Hinge

With adjustable friction hinges, the amount of friction exerted by the hinge can be adjusted to the desired strength simply with a hex key or similar tool.

This can be helpful when replacing a door with one of a different weight so that you still get the same performance. It’s also handy if a worker prefers a door to move more easily or more stiffly, since the issue of how hinges work can change depending on the people using them. Having adjustable friction hinges can have other advantages as well, such as when it comes to irregular door shapes and uneven door weights on different hinges.

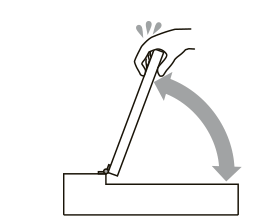

Detent Torque Hinge

Closes completely

Spring-back

A mechanical detent is designed at the closing point to eliminate spring back ensuring that the lid remains completely closed.

No additional catches are required which contribute to a clean interior.

Spring-back is a phenomenon that lids cannot completely close to 0° position due to torque. It is also called backlash.

Spring-Assist Torque Hinge

+

Retaining torque

The built-in spring makes lids feel lighter to open and close.

See productsApplications and Case Studies

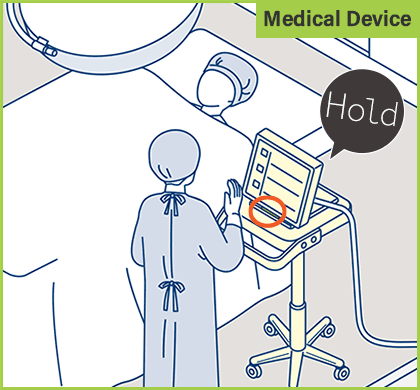

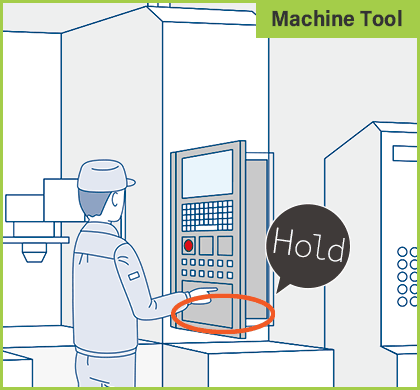

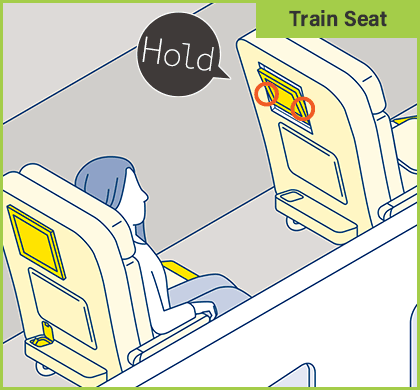

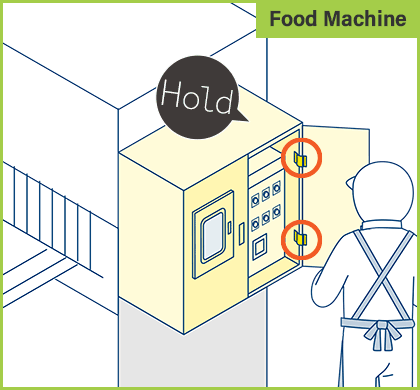

Torque hinges are ideal for adjusting the angles of machine covers, monitors, and lighting fixtures. They play a versatile role in various industries such as medical equipment, machinery, transportation, and food processing machinery.

Applications

Case Studies

Provides torque stability in both directions and suitable for monitor screens.

Selection of Torque Hinge

Choose a torque hinge for your project.

The torque varies depending on the product.

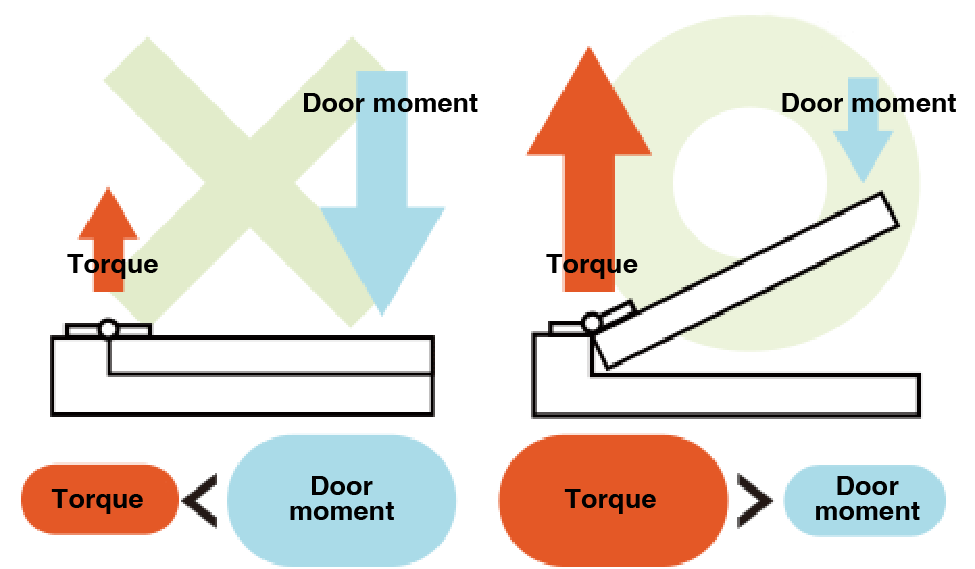

Door Moment

A moment is the turning effect of a force.

A door moment is the force with which a door rotates to open or close.

If the torque is less than door moment, the door will not free-stop.

Torque Tolerance

Torque tolerance also needs to be considered when selecting a torque hinge.

For example, 3 N·m torque with ± 20% tolerance has lower limit of 2.4 N·m. Therefore, doors may not free-stop when the door moment is 2.5 N·m.

For more information about door moment, please click here.