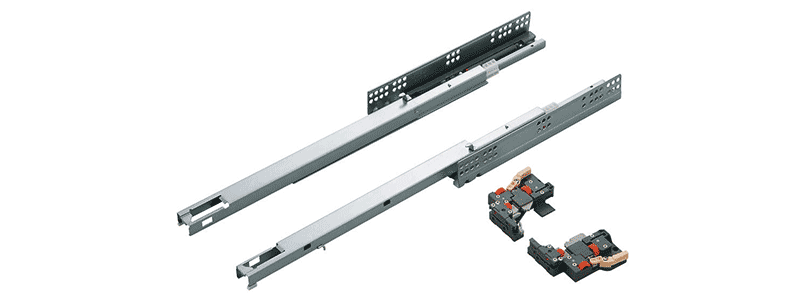

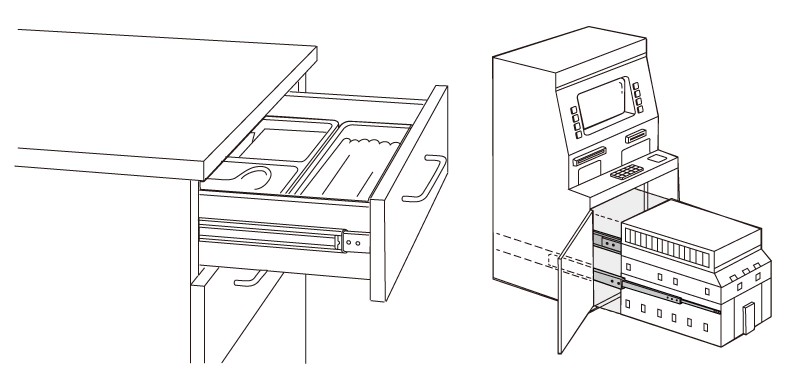

Drawer slides are attached to drawers to facilitate easy and effortless opening and closing, even with heavy loads. Usually, two drawer slides are used on a single drawer.

The application of drawer slides is not limited to drawers for furniture, kitchens and shop furniture; they are also used as a linear motion mechanism to move equipment inside ATMs and server racks.

- Company Top

- About our Products

- Hardware Basics

- Drawer Slides

Drawer Slides Hardware Basics

Drawer slides are used for various applications, including furniture drawers and equipment.

This section provides an introduction to the fundamentals of drawer slides, including their various types and how to choose a suitable product.

Contents

What are drawer slides?

Drawer Slide's Components and Mechanism

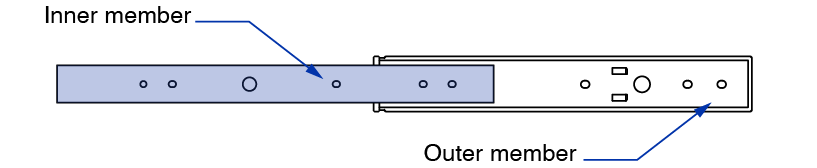

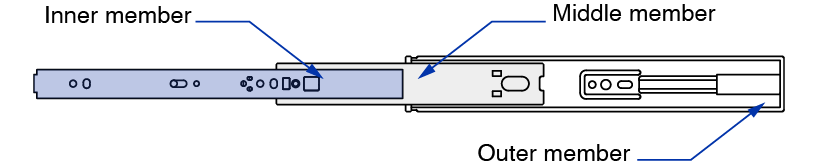

A drawer slide is composed of the following parts.

- The outer member is mounted to the main body of the furniture or its housing (also called an outer rail or cabinet member)

- The inner member is the movable component and is mounted to the drawer (also called an inner rail or drawer member)

- The middle member is placed between the outer member and the inner member (also called the middle rail)

- Steel balls that are placed between the rails to bear the load of sliding*

- Retainer to retain the steel balls

With the load distributed among multiple balls, the drawer can move smoothly with minimal effort. This type of drawer slide is sometimes referred to as 'ball bearing type' or 'bearing type'.

*Some of our products are roller type.

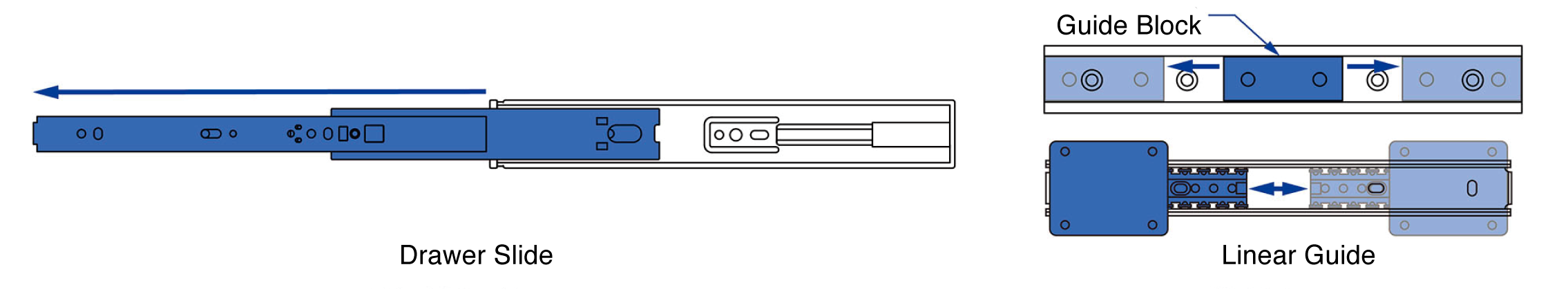

Although drawer slides are similar in shape to linear guide, the difference between them is described below.

- Drawer Slide:

- The inner and middle members protrude from the outer member.

- Linear Guide:

- The guide block (inner rail) does not protrude from the guide.

Types of Drawer Slides

Mounting Locations

Side Mount

A drawer slide is mounted on either side of a drawer, with one on the right and the other on the left. The outer member is mounted to the main body of the furniture or its housing and the inner member is mounted to the drawer.

For furniture, slides with a thickness of about 12.7 mm are often used.

- Mounting Example

-

Under Mount

Under mount slides are mounted on the bottom of a drawer and concealed when the drawer is opened. In addition, less space is needed between the drawer bottom face and the housing.

The C203V (shown in the image below) is ideal for glass showcases because it is invisible when seen from the housing, as well as from the sides.

- Mounting Example

-

Extension (Travel Length) Types and Their Differences

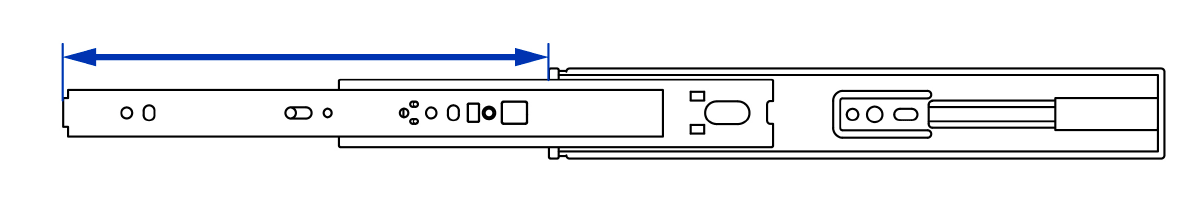

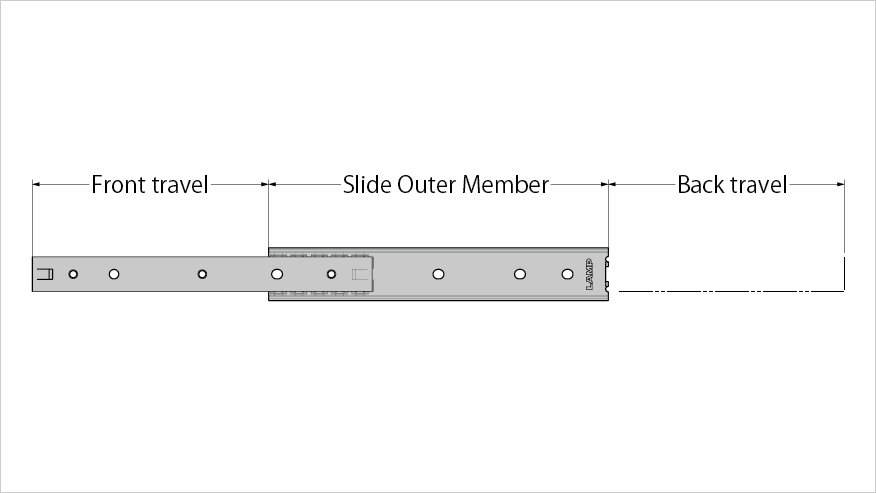

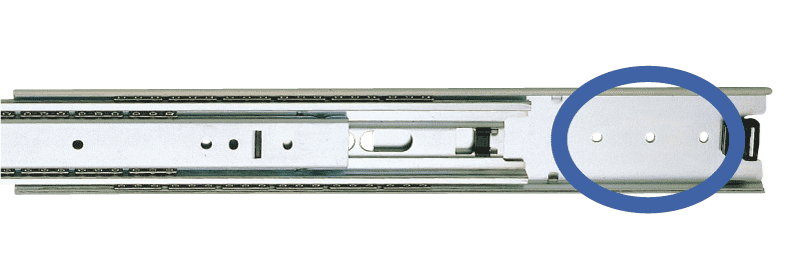

Drawer slides enable drawers to open to different lengths, depending on their type, such as 3/4 extension (opening 3/4 of the way) or full extension (opening the drawer all the way out). The travel length of a drawer slide is how far the inner member can be pulled out from the outer member*. As shown in the image, it is calculated by subtracting the length when the rails are fully closed from the length when they are fully extended. Travel length is also called a stroke length.

*Please refer to the drawings of each product.

3/4 Extension Slide

3/4 extension slide slides do not allow a drawer to open fully because about 1/4 of the length of the inner member stays inside the outer member (see video above).

3/4 extension slides have minimal thickness so drawers can have wider interior dimensions and greater width compared to those that use full-extension drawer slides.

Full Extension Slide

The inner member of a full extension drawer slide can be fully extended from the outer member (see video above).

This allows the entire length of the drawer to be pulled out from the cabinet. This feature provides convenient access to the contents of the drawer, making it easier to retrieve and store items.

*Some 3/4 drawer slide do not allow the inner member to be pulled out fully from the outer member.

Mechanisms/Functions

Self & Soft Closing

By using drawer slides equipped with a self-closing and soft-closing mechanism, you can gently and slowly close a drawer (soft close) and it will return to the cabinet automatically without requiring manual pushing (self close).

Drawer slides are not only utilised to enable a smooth and gentle closure of drawers but are also employed as a buffer to minimize the impact on precision instruments inside machines. The self closing feature also prevents rebounding when the drawer is closed.

Push Open

Drawer slides with a push-open mechanism allow you to open drawers just by pushing them inward. You can almost effortlessly open it using your elbow, even when your hands are full. By utilising this type of drawer slide, you can create furniture or equipment that does not require handles or knobs, enabling users to effortlessly open the drawers by simply pushing them.

The push-open mechanism requires the drawer to be pushed beyond its normal closing position, which necessitates a specific amount of clearance to allow for the push-in action.

Full Open Lock

The locking mechanism locks the drawer slides when in the fully open position. The lock can be released by pushing a lever.

Hold Open/Closed Feature

Drawer slides with the hold open feature allow drawers to be held temporarily in its full open position. The drawer is released from the hold open position with just a push. Slides with the hold closed feature allows a drawer to be held temporarily in its fully close position.

The drawer is released from the hold closed position just by pulling (see video above).

Detachable

Detachable type slides are designed with an inner member that can be detached from the outer member. This feature allows for easy installation, as the slides can be mounted with the drawers separated from the cabinet. This type of slide is widely used for wooden drawers.

It is important to note that the inner member of a detachable slide should not be used with a different outer member. Using the inner member with a different outer member can cause malfunctions, such as jerky movement. This is because the size of each rail is designed to fit perfectly inside one another.

2-Way

2-way slides allow for travel from both the front and back sides of the application.

Silent Type

Silent type slides are designed to reduce the metallic noise from rails produced when a drawer is completely opened or closed.

Friction Type

Before the development of the detachable type, the friction type was commonly used when slide detachment was required.

For friction type drawer slides, frictional resistance prevents the slides from detaching when they are fully extended. However, by applying additional force and pulling the slide beyond its fully extended position, the drawer can be removed.

If a drawer does not move smoothly or slides only a short distance, or if it becomes difficult to slide, it may be due to a phenomenon called 'creep.'

The creep phenomenon, also known as ball creep, occurs when the balls within a drawer slide gradually shift to one side and cluster with repeated use of the slide. Over time, the distance that the balls can travel becomes shorter than the slide's travel length.

A creep phenomenon can be eliminated by forcing the drawer slide to extend to its full length. You must, however, pull it slowly; pulling it quickly or giving it a strong jolt can cause damage.

Ball creep is more likely to occur when the drawer slides are not mounted parallel to each other, the full travel length is not used, the drawer slide does not slide smoothly, or when the slide is used vertically, etc.

How to Choose a Drawer Slide

Check the Total Weight of the Load

The load capacity of a drawer slide is typically indicated as "load capacity N/pair" or "load capacity kgf/pair," denoting the weight that a pair of slides can support. Use slides with a load capacity larger than the total weight of the load. For example, if they are used for a drawer of a piece of furniture the total weight means the weight of the drawer itself and its contents.

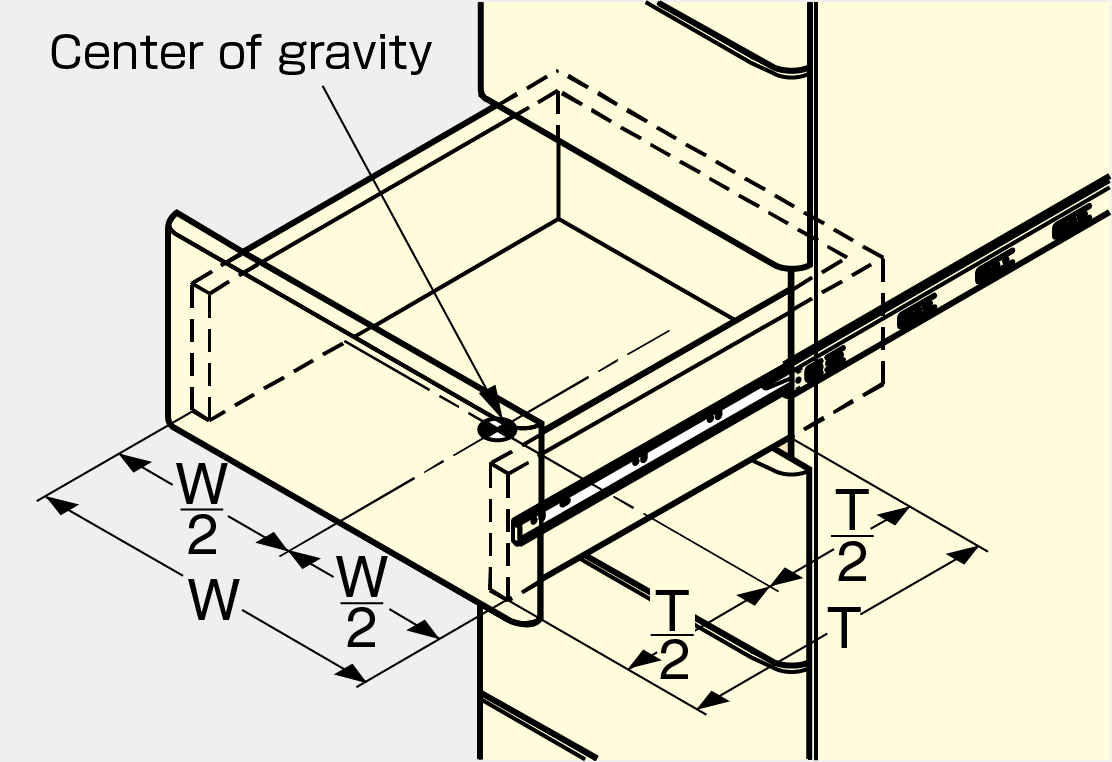

Please also note that, in our specifications, load capacity refers to the weight that a pair of slides can bear when a drawer is open with the center of gravity of the total weight aligned with the drawer’s center (the center of the travel distance and that of the width cross), as shown in the figure. It does not refer to tip load, the load that the front area can bear.

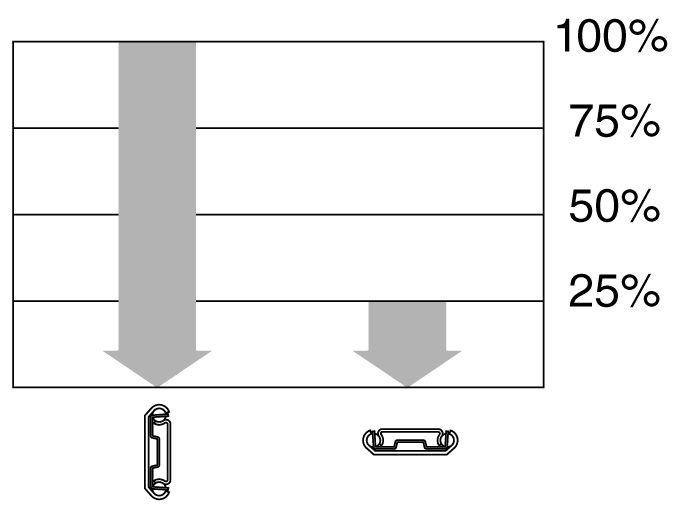

Slides intended for vertical use are not designed to bear the weight of a load in the horizontal position and thus cannot be used in the horizontally. When using our drawer slides in a horizontal position, please note that the load capacity is reduced to 25% or less of the specified capacity found on our website and catalogues. It's important to take this into account when selecting the appropriate slide for your application to ensure proper function and safety.

For horizontal applications, please use under mount slides.

Check the Mounting Surface for the Slides

Slides are categorised into two types: those for use on wood and those for use on sheet metal.

When working with wood, it can be challenging to achieve a precise clearance between the drawer and the cabinet (housing). As a result, it's important to choose slides that are designed to account for dimensional errors. By selecting slides that can accommodate these variations, you can ensure that your drawers will function smoothly and reliably.

For Wood Use

With Tabs

The outer member of drawer slides designed for use with wooden surfaces features a U-shaped cutout with a flexible tab at its center. This tab can expand slightly towards the cabinet to compensate for small dimensional errors that may occur during installation.

Under Mount

Undermount slides that are appropriate for wood applications are those that are affixed to the bottom face of the drawer. Since the drawer sits on top of the drawer slide, it can be installed without requiring high precision in terms of its dimensions.

In woodworking applications, it is generally advisable to choose drawer slides that are both undermount and equipped with outer member tabs.

With L-shaped Angle

Drawer slides with L-shaped angles that are suitable for woodworking applications have cutouts on their inner members and can be attached to the backside of shelf boards using screws. The screw holes on the angled portion are elongated, allowing for some tolerance to absorb minor dimensional errors.

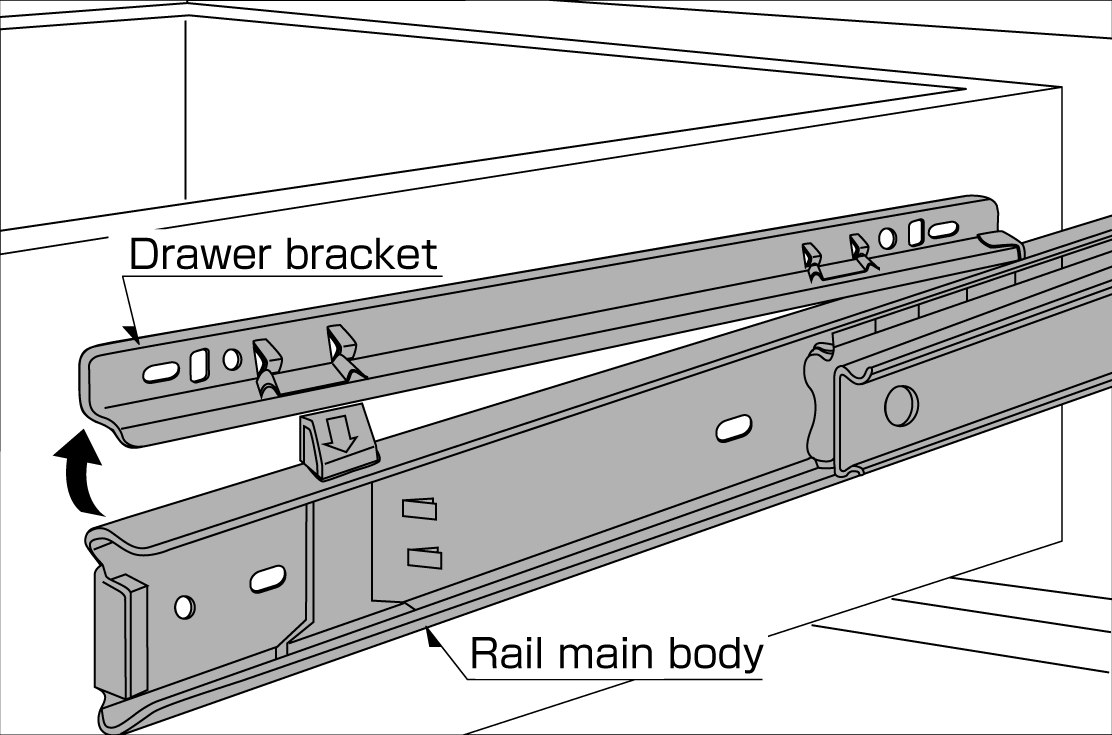

With Drawer Bracket

Drawer slides equipped with a component called a "drawer bracket" are suitable for woodworking applications and do not have tabs.

The drawer bracket is mounted onto the drawer, while the rail main body is attached to the cabinet. Since the drawer bracket sits on top of the rail main body, there is a slight gap at the joint that can accommodate minor dimensional errors. This design allows for some tolerance in the installation process.

For Sheet Metals

Unlike those suitable for wood applications, slides suitable for sheet metals do not have any cut outs on their outer members. The cabinet and drawers they are mounted to must be accurate in size.

*Except for the under mount type, the slides for wood applications introduced above can also be used with sheet metals.

Select Travel Length and Functions

Select necessary specifications from the extension (travel length) types, mechanisms and functions above.

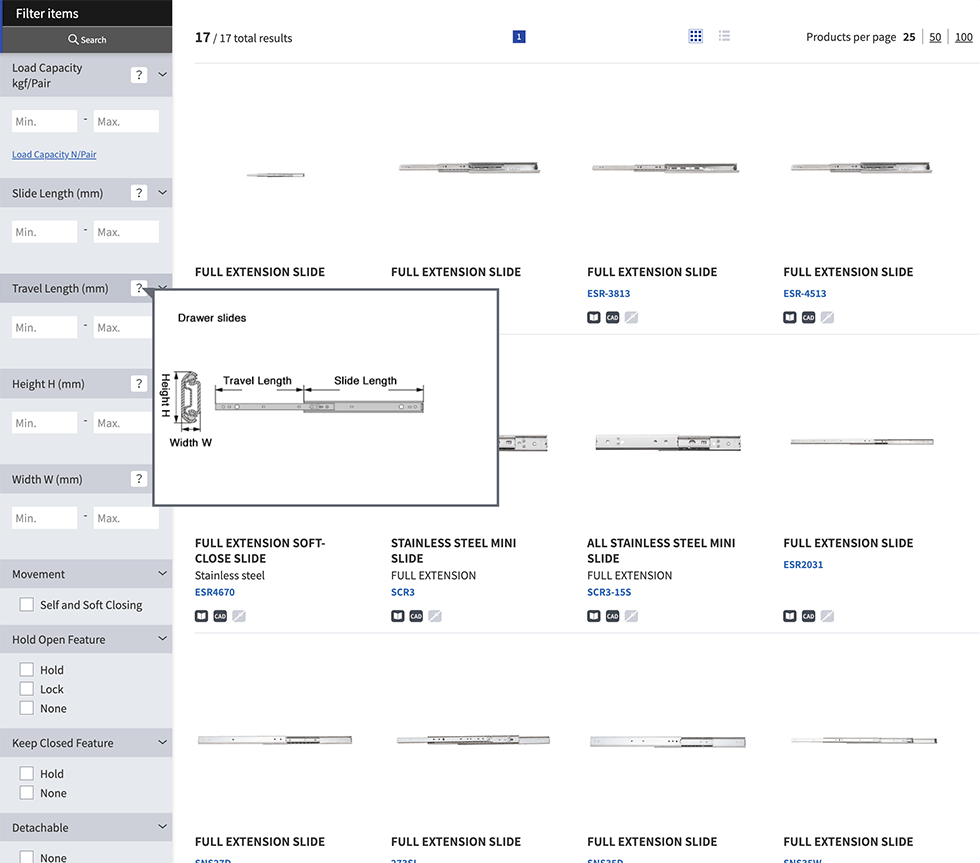

You can use the search filters on our website to easily find drawer slides with the specifications you need.

The product specifications, such as Load Capacity, Travel Length, and Mechanism, are listed on the left-hand side of the webpage. By entering numeric values or checking relevant boxes, you can easily filter and display the products that meet your requirements. Clicking the description button next to each filter item opens a window with descriptions and diagrams, so you can easily filter products even without knowledge of technical terms.

Find Drawer Slides with Search Filters

Main Drawer Slide Products

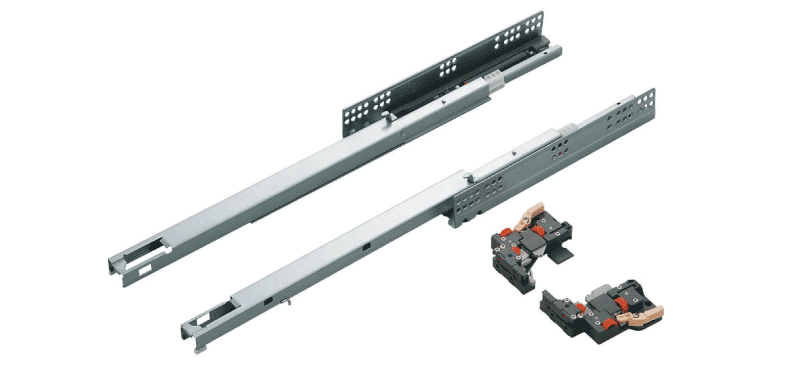

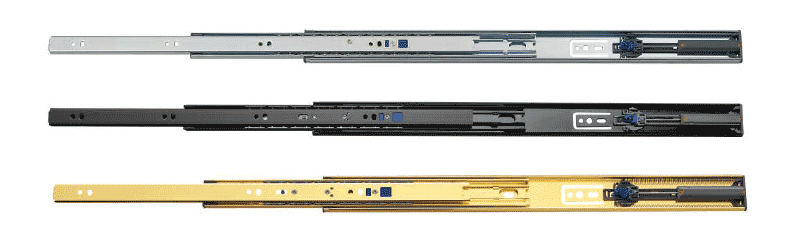

Mounting position: Side mount

Extension type: Full extension slide

Mechanism / functions: Self & soft closing, Detachable, Silent

The slide height is compact while still being able to bear a significant load. Black and gold colours are also available, enabling you to choose the one that complements the color scheme of your furniture.

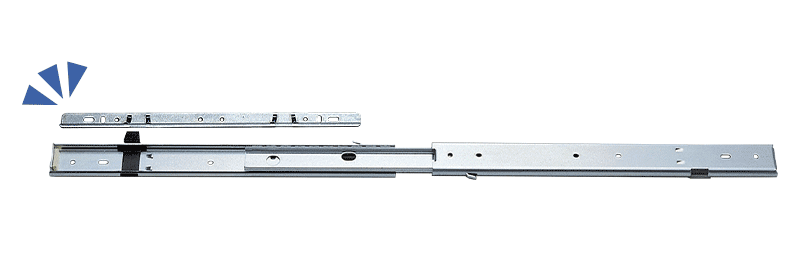

Mounting position: Side mount

Extension type: Full extension slide

Mechanism / functions: Self & soft closing, Detachable, Silent

The proprietary mechanism reduces backlash in closing, allowing a drawer to open even when the area of the front board being pushed (push area) is off the center to some extent.

An extremely small drawer slide. These are recommended when you need to move a small component just a little bit inside an inspection device or analyzer.

Mounting position: Under mount

Extension type: Full extension slide

Mechanism / functions: Self & soft closing, Detachable

Under Mount Drawer Slide 2020 provides three-dimensional adjustment capabilities, enabling you to give your furniture with multiple drawers a flawless finish with consistent drawer gaps. This offers excellent workability as the position of a drawer can be adjusted after installation, without the need to take off the slides.