The Torque Hinge HG-TA was adopted for a wrapping machine for products.

The following is an example of how the free stop function improves the operation of the machine, without compromising the design of the equipment.

Key Issues

- The machine cover was heavy to lift and did not have free-stop, so there was a risk of finger entrapment during operation.

- The objective was to conceal the hinges when the cover was closed, but the absence of a back plate in the equipment's design restricted the options for compatible hinges.

Product Information

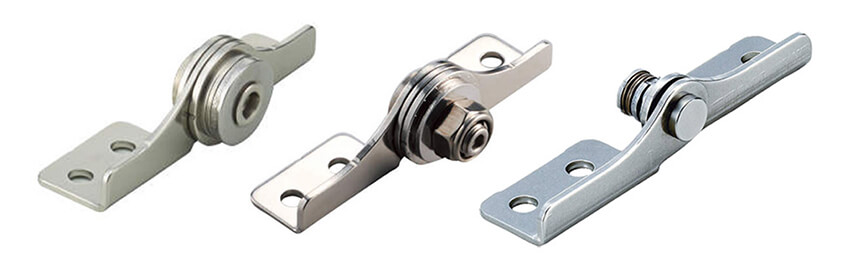

TORQUE HINGE / HG-TA

— The torque mechanism uses a "disc structure", in which a fixed disc is sandwiched between two movable discs to generate friction, resulting in a compact shape with a short shaft.

— Some types have wiring holes in the shaft.

— The type with wiring holes has passed our opening and closing tests 50,000 times, and the type without wiring holes passed 20,000 times.

*Information as of 25 April 2023.

The Solution

- The HG-TA model significantly enhanced the safety of the machine by providing a durable solution that securely holds the metal lid in place.

- Proposed the best torque hinge based on the customer's needs. The HG-TA hinge can accommodate special cover shapes.

A compact, powerful torque hinge that enhances safety

After consulting with the client, who expressed the need for a product that addresses finger entrapment risks during the opening and closing of the upper cover, incorporates free-stop functionality, and allows for a concealed hinge installation, we recommended the Torque Hinge HG-TA. Despite its compact size with a hinge length of 18.5mm, this hinge provided a stable torque of up to 45.9kgf, fulfilling the client's request to keep the hinge concealed while enabling free-stop operation of the upper cover.

Efficient Design Integration via Disk Mechanism for Compact Design

Versatile variety of hinges to meet machine operation and design requirements

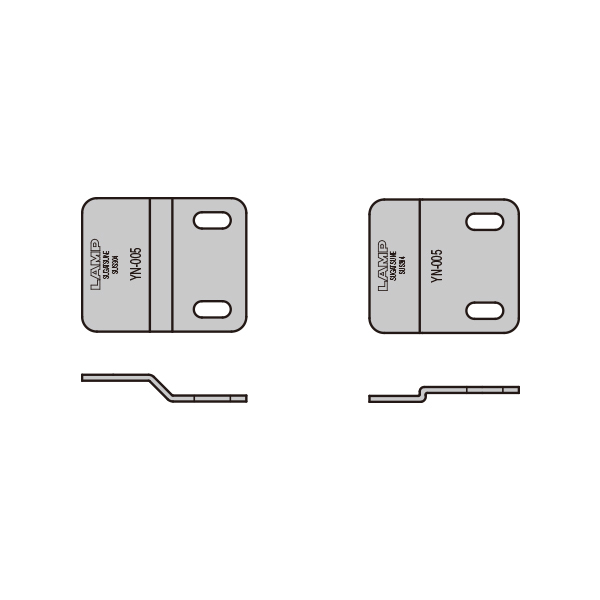

The HG-TA type was used in this case study, but there is a multiple variations of these hinges that have the same shape. There is a wide array of specifications available, so you can find the perfect hinge for your needs. These options include an all-stainless steel hinge type that offers excellent corrosion resistance, a type with adjustable torque, and a type designed to minimize recoil (springback) when opening and closing the hinge.