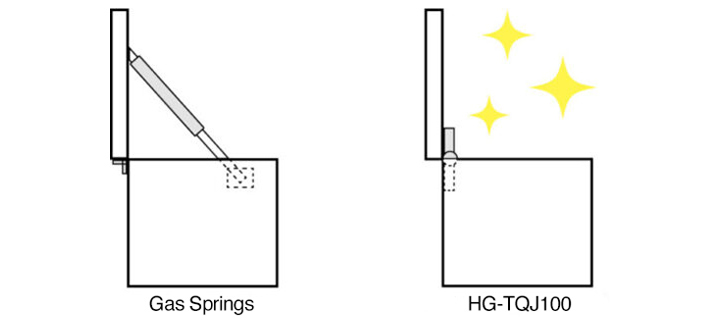

A smaller alternative to a gas spring was needed to facilitate maintenance and reduce maintenance costs on a semiconductor chip inspection line

The adjustable one-way torque hinge HG-TQJ100 was integrated into machines used for semiconductor inspection lines because of its compact size and its ability to significantly improve the operability of the machine maintenance doors.

Key Issues

- When gas springs were used the machine maintenance door only opened to the highest position and could not be stopped at the appropriate height for the operator.

(→ Free stop function (torque hinge)) - The free stop function is an important feature, but if torque is applied in both directions, the door feels heavy when it is opened. Opening and closing the machine door must both be smooth (need less resistance when opening).

(→ one-way function) - The door sizes of the inspection machines varied in size, but the customer wanted to use one hinge to fit all.

(→ Adjustment functions) - Replacement of parts due to gas loss (caused by ageing) and lack of power.

(→ No gas is used, high durability (cleared 20,000 open/close tests) and reduced maintenance costs).

Product Information

Adjustable one-way torque hinges HG-TQJ100

— Torque hinges with in one direction torque. This means that there is very little torque in the opposite direction, allowing smooth operation of doors and lids.

— Torque can be adjusted.

— Torque adjustment area is capped for aesthetic appeal.

The Solution

- The change from gas springs to the HG-TQJ100 torque hinges allowed the maintenance door of the machine to be opened at any angle due to its free stop function.

- The HG-TQJ100 is a one-way torque hinge, so the maintenance door can be opened using a normal amount of force.

- The adjustable torque allows it to be used on doors of various sizes. In addition, the hinge itself is compact and can be replaced easily, reducing maintenance costs.

- The use of torque hinges has eliminated concerns such as gas leakage and reduced maintenance costs.

Free-stop movement for ease of use and safety

Because gas springs were originally used for the lid of the inspection system, the door would rise to its highest position when opened, making it impossible to stop the door at the appropriate height for the operator. However, by switching to HG-TQJ100 torque hinges, a free stop function was added and the door could then be opened according to the operator’s height.

Furthermore, although the lids of the inspection equipment varied in size, the torque value of the HG-TQJ100 could be adjusted between 0-10 Nm. This made it possible to accommodate multiple door sizes and match the operator's torque preference.

The free stop function also improved safety by reducing the risk of injury due to accidental door closure.

One-way torque for smooth operation

The free stop function is an important feature, but if torque is applied in both directions, opening the door would feel very heavy. However, the HG-TQJ100 has a one-way torque specification, meaning that very little torque is applied when opening the maintenance door. This allows for a smooth opening. Torque is only applied when pulling the maintenance door in the closing direction.

The compact size of the hinge and multiple functionalities helped reduce maintenance frequency and maintenance costs

When gas springs were used, they had to be replaced frequently as the gas contained in the gas spring would deplete.

The HG-TQJ100 torque hinge, on the other hand, can maintain its torque functionality for a longer period of time.

Additionally, gas springs were difficult to replace due to limited space inside the machine, but because the HG-TQJ100 combines both the hinge and torque functions in a compact design, it occupies significantly less space within the machine.

Furthermore, because the torque hinge is a standard size, maintenance management and maintenance costs were decreased. As a result, cost-effectiveness was also improved.